Antifoam-Fermentation

Jan 06, 2023Defoamer For Fermentation

During the fermentation process, the foam-active substances, air and turbulences contribute the excessive foam. Generally, carbohydrates as material, are converted into sugar substrates, enzymes, starches and proteins, which promote the foam appearance. In addition, amino acids and proteins generated by microorganism can cause large of foam activity.

Antifoam Mechanism:

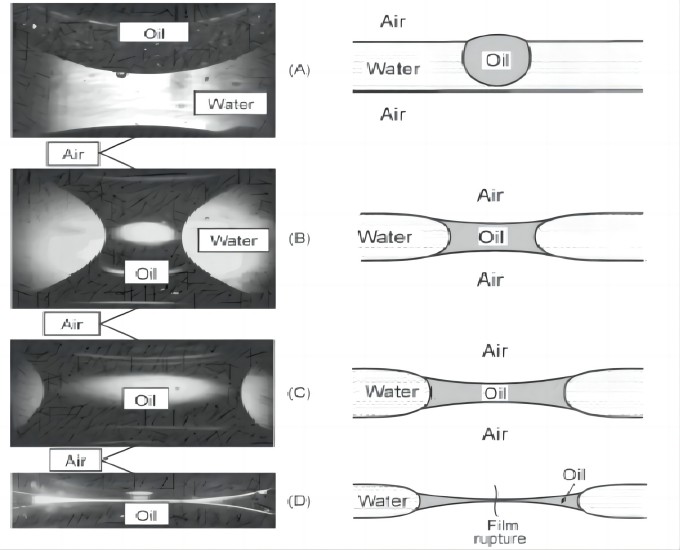

1. The spread of the antifoaming agent replacesthe foaming molecules on the upperlayer of the foam bimolecular membrane, foaming a film with very low strength;

2. In the process of spreading, part of the solution of the adjacent surface layer will be taken away, reduce the stability of the foam and make it easy to destroy.

As a manufacturer of foam control agents, RICKMAN provides a series of defoamer solutions for molasses fermentation, ethanol/ alcohol fermentation, distilleries, sugar refineries etc. Silicone defoamers and polyether defoamers provide excellent breaking foam and antifoaming performance for fermentative processes. And adding procedure depends on the fermentation progress. The usage of antifoams can be adjusted according to the whole fermentation.

Our products:

RK-8636 RK-F0080 RK-0010 RK-700P

Brochure: