Antifoam-Pulp And Paper

Jan 06, 2023

Defoamers And Antifoams For Pulp And Paper Industry

The foam appears during pulp production, due to the black liquor that is comprised of NaOH, Na25, tall oil soap, rosin soap, lignin, cellulose and other organic compounds. And paper machines are very sensitive to foam generation through chemical interactions on the machine such as sizing, fines, dry strength, wet strength. Foaming can reduce pulp and final paper quality and quantity.

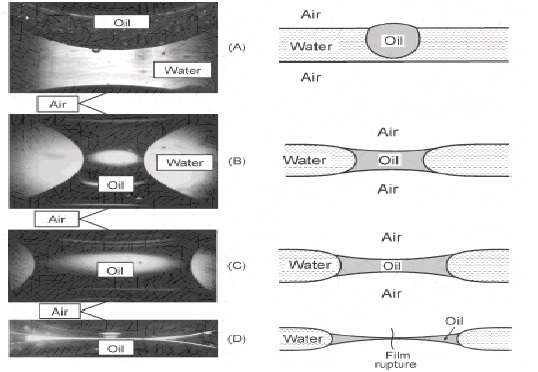

Antifoam Mechanism:

1. The spread of the antifoaming agent replaces the foaming molecules on the upperlayer of the foam bimolecular membrane, foaming a film with very low strength;

2. In the process of spreading, part of the solution of the adjacent surface layer will be taken away, reduce the stability of the foam and make it easy to destroy.

Antifoam for pulp process:

Anionic surfactants are formed by chemical reaction between alkali and wood or Straw grass during cooking process.

Silicone defoamer or non-silicone defoamer are usually used for pulp preparation.Silicone and non-silicone defoamer has it’s own focus according to different raw materials.Silicone defoamer series are more efficient in pulp washing with hard wood and soft wood as raw materials. Silicone based defoamer series are usually continuously added to the filtered black liquor during pulp washing process.

Antifoam for Paper Machine:

Paper making process is an important process for paper forming. A lot of additives, such as sizing agent, retention agent, filter aid,wet strength agent,dry strength agent etc are to be used to form paper with certain performance. These additives are added in different dosing points. And it’s easy to form foaming during white water circulation in closed system.

Paper machine defoamer is usually added in the points with a lot foam, for instance, underwire white water chest or white water tank. Defoamer will be added continuously in several dosing points to give full play of defoamer performance.It will not only achieve good performance but also save cost.

Antifoam for paper sizing and coating:

Because agent itself is also a surfactant, which is mixed air during operation.Paper sizing defoamer usually added at the sizing press out the section.

Antifoam for paper coating is usually added during the formulation of coatings.Styrene-butadiene latex is the latex make coated art paper coating and can easily cause foam when dispersing pigments or filliers at high speed.

Foam Control Agents For Water treatment:

In water and wastewater treatment industries, the fluids contain bacteria, chemicals, and other compounds hazardous to human health. The causes of foam in different water treatment plants are varied. Foam can be caused by biological activity, mechanical action, chemical contamination, surfactants or some polymer. Regardless of the cause, excessive foams are unacceptable and often interfere with operations.

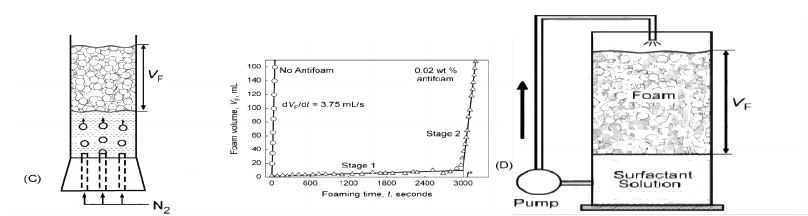

Antifoaming and foam suppression ability test methods could be shaking test, bubbling test and cyclic bubbling test.

Characteristics :Test under strong foaming condition.

This experiment is widely used for characterization

(1)Foaming properties of surfactant solutions

(2)Study and application of foam stability in the presence of defoamer.

The bubble elimination and inhibition performance is tested by Ross-Miles foam tester.

Defoamers and antifoams from Rickman enable manufacturers to increase productivity and decrease production costs thanks to their defoaming and deaeration properties!

Our Range of defoamers includes:

*Silicone defoamers: for the pulp washing black liquor, and wastewater treatment

*Fatty alcohol defoamers: for paper making white water wet end, and the wastewater treatment

*Polyether defoamers: for the paper making white water wet end, and the paper sizing and coating treatment

*Mineral oil defoamers: for the paper sizing and coating treatment

RICKMAN DEFOAMER SOLUTION FOR PULP AND PAPER (Brochure)

Our products:

Defoamer for Pulp process(kraft/sufite pulping process): RK-10S RK-20S RK-5DS RK-8455S RK-P582

Antifoam for Paper machine(paper making white water wet end): RK-F0020 RK-F0090 RK-F0080 RK-50P RK-0010 RK-0080 RK-300P

Antifoam for paper sizing and coating process: RK-300P RK-0010 RK-50P RK-203

Antifoam for water treatment: RK-F0080 RK-400P RK-800P RK-700P RK-8636 RK-0036 RK-1215A